Our Products

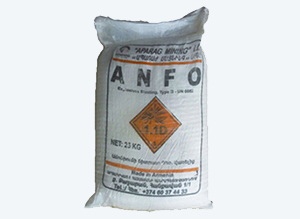

ANFO – Ammonium Nitrate-Fuel Oil

Thermodynamic and Technical Properties

The detonation velocity depends on cartridge diameter and cartridge confinement. The ideal detonation velocity is calculated by "JC3" thermodynamic code as a function of chemical composition.

- Ideal detonation velocity - 4850 m/s

- Ideal detonation pressure - 48960 atm

- Ideal detonation temperature - 2946 K

- Velocity of detonation at 125 mm cartridge - 4000-4200 m/s

- Density - 0.78-0.80 gr/cm3

- Heat of explosion - 3.89 Mj/kg

- Water resistance - Poor

Transport

UN classification 1.1 D, UN 0241. Explosive, Blasting. Type E.

Performance

"Anfo" is an oxygen-balanced mixture of prilled porous ammonium nitrate and fuel oil (at ratio of 94.3% AN, 5.7% FO), manufactured with total process control. It is not water-resistant.

High Safety Standards

"Anfo," in comparison with other explosives containing nitroglycerine, is more resistant to initiation by both friction and impact. Furthermore, during storage and usage, it does not cause headaches or other health risks.

Product Range

"Anfo" is packed in 25 kg and 50 kg double-layer bags. For special orders, other sizes can be produced.

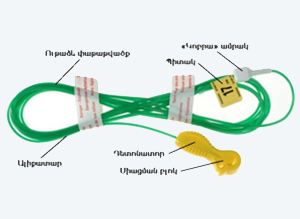

Armdet HTD non-electric, short delay, trunk lines assemblies provide out-of-hole delays in non-electric blast patterns. Used in conjunction with "Armdet MS" in-hole shock tube detonator assemblies, "Armdet HTD" assemblies provide flexibility in blast design and are easy to use. They can be used in quarries, surface coal operations, open pit and underground mines, and construction projects to provide accurate surface timing.

Armdet HTD Storage

For best results, "Armdet HTD" should be stored in moderate temperatures and dry conditions in a well-ventilated, approved detonator magazine. The manufacturer guarantees the quality of the product for a two-year period, if stored in appropriate conditions.

Hazardous Materials Shipping Description

Detonators Assemblies, Non-electric, Class and Division 1.1 B, UN 0360, PG II EX 9106258.

Armdet HTD assemblies have 4 main components:

- Low-power capsule assembled in the interior of a surface connector.

- Green shock tube, which conveys the signal to the delay capsule. When the tube is initiated, it transmits through the interior a low-energy shock wave, which initiates the delays inside the capsule.

- Label delay element that indicates the serial number, nominal time, the length of the tube and the lot number associate with the date of manufacture, giving the user the reliability of the process of tracking and/or traceablility for each unidirectional surface connector.

- Cobra connector, which allows connection between the detonating cord and the non-electric tube, if required.

| Delay Numbers and Times | |

| Time (ms) | Connector Block Color |

| 9 | Green |

| 17 | Yellow |

| 25 | Red |

| 33 | Yellow |

| 42 | White |

| 65 | White |

| 100 | Black |

| 200 | Orange |

| Length (meters) | Quantity per case |

| 4 | 150 |

| 6 | 100 |

| 9 | 50 |

| 12 | 50 |

| 15 | 40 |

| 18 | 40 |

For special orders, other lengths may be available.

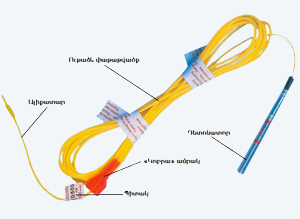

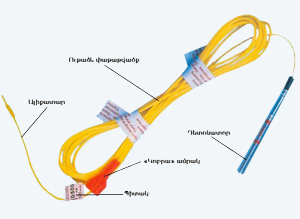

Armdet LP detonator assemblies provide long-delay, non-electric initiation of underground blast patterns. Used in conjunction with detonating cord trunk lines, "Armdet LP" assemblies, in 27 delay periods, provide flexibility in blast design and are easy to use. They can be used in underground development and production blasting, construction tunneling, and shaft sinking.

Storage

For best results, "Armdet LP" should be stored in moderate temperatures and dry conditions in a well-ventilated, approved detonator magazine. The manufacturer guarantees the quality of the product for a two-year period, if stored in appropriate conditions.

Materials Shipping Description

Detonators Assemblies, Non-electric, Class and Division 1.1 B, UN 0360, PG II EX 9106258.

Delay Numbers and Times

| Number | Time (ms) | Numb. | Time | Numb. | Time |

| 0 | 0 | 3 | 1200 | 11 | 4000 |

| 1/4 | 100 | 4 | 1400 | 12 | 4500 |

| 1/2 | 200 | 5 | 1600 | 13 | 5000 |

| 3/4 | 300 | 5 1/2 | 1800 | 14 | 5500 |

| 1 | 400 | 6 | 2000 | 15 | 6000 |

| 1 1/4 | 500 | 7 | 2250 | 16 | 6500 |

| 1 1/2 | 600 | 8 | 2500 | 17 | 7000 |

| 2 | 800 | 9 | 3000 | 18 | 8000 |

| 2 1/2 | 1000 | 10 | 3500 | 19 | 9000 |

| Length (meters) | Quantity per case |

| 3 | 200 |

| 4 | 200 |

| 5 | 200 |

| 6 | 150 |

For special orders, other lengths may be available.

Armdet MS detonator assemblies provide short-delay, non-electric initiation of blast patterns. Used in conjunction with detonating cord trunk lines or order non-electric surface delay systems, "Armdet MS" assemblies, in 28 delay periods, provide flexibility in blast design and are easy to use. They can be used in surface or underground mines, quarries, or construction projects.

Storage

For best results, "Armdet MS" should be stored in moderate temperatures and dry conditions in a well-ventilated, approved detonator magazine. The manufacturer guarantees the quality of the product for a two-year period, if stored in appropriate conditions.

Hazardous Materials Shipping Description

Detonators Assemblies, Non-electric, Class and Division 1.1 B, UN 0360, PG II EX 9106258.

Delay Numbers and Times

| Number | Time (ms) | Numb. | Time | Numb. | Time |

| 0 | 0 | 10 | 250 | 20 | 500 |

| 1 | 25 | 11 | 275 | 22 | 550 |

| 2 | 50 | 12 | 300 | 24 | 600 |

| 3 | 75 | 13 | 325 | 26 | 650 |

| 4 | 100 | 14 | 350 | 28 | 700 |

| 5 | 125 | 15 | 375 | 30 | 750 |

| 6 | 150 | 16 | 400 | 32 | 800 |

| 7 | 175 | 17 | 425 | 36 | 900 |

| 8 | 200 | 18 | 450 | 40 | 1000 |

| 9 | 225 | 19 | 475 |

| Length (meters) | Quantity per case |

| 4 | 200 |

| 5 | 200 |

| 6 | 150 |

| 7 | 150 |

| 9 | 100 |

| 12 | 60 |

| 15 | 60 |

| 18 | 50 |

| 21 | 50 |

| 25 | 40 |

| 30 | 30 |

| 37 | 30 |

| 45 | 30 |

For special orders, other lengths may be available.

Armex is designed for hard rock conditions. It can be by a booster. "Armex" has high heave and fragmentation characteristics.

Product Range

The following sizes of "Armex" are available in 20 kg cardboard boxes. For special orders, other sizes may be available.

| Standard dimensions | Cartridge weight |

| 75 х 450 mm | 2500 gr |

| 90 х 500 mm | 4000 gr |

| 125 х 650 mm | 10000 gr |

| 140 х 520 mm | 10000 gr |

| 185 х 600 mm | 20000 gr |

Performance

"Armex" are waterproof emulsion explosives.

High Safety Standards

"Armex," in comparison with other explosives containing nitroglycerine and nitroglycol, is more resistant to initiation by both friction and impact and is much safer. Furthermore, during storage and usage, it does not cause headaches or other health risks.

Initiation and Charging

"Armex" in all diameters is initiated by cap sensitive explosives such as "Armex Power" or "Armex Power Plus." If the cartridge is slit from sides during the charging, the hole diameter will be covered completely with the explosive, and this will increase the blasting performance.

Storage

"Armex" should be stored in a dry, well-ventilated magazine, in accordance with the regulations.

Packaging

All "Armex Power" products are supplied in flexible sleeve durable packaging.

Transport

UN classification 1.1 D, UN 0241. Explosive, Blasting. Type E.

Armex Power has exceptional shock and heave characteristics and is the ideal explosive to initiate "Anfo" and other booster sensitive explosives.

Product Range

The following sizes of "Armex Power" are available in 20 kg cardboard boxes. It is cartridged in plastic bags with clips at both ends and is tear-resistant. Other sizes may be available for special orders.

| Standard dimensions | Cartridge weight |

| 50 х 225 mm | 500 gr |

| 50 х 450 mm | 1000 gr |

| 65 х 250 mm | 1000 gr |

| 65 х 500 mm | 2000 gr |

| 75 х 200 mm | 1000 gr |

| 90 х 150 mm | 1000 gr |

| 90 х 290 mm | 2000 gr |

| 90 х 350 mm | 2500 gr |

Performance

"Armex Power" is a waterproof cap sensitive emulsion explosive. "Armex Power" has exceptional heaving and fragmentation characteristics. "Armex Power" is the ideal explosive to initiate "Anfo" and/or other booster sensitive explosives.

High Safety Standards

"Armex Power," in comparison with other explosives containing nitroglycerine and nitroglycol, is more resistant to initiation by both friction and impact and is much safer. Furthermore, during storage and usage, it does not cause headaches or other health risks.

Thermodynamic and Technical Properties

- Ideal detonation velocity - 6345 m/s

- Ideal detonation pressure - 119350 atm

- Ideal detonation temperature - 2502 K

- Density - 1,18 gr/cm3

- Water resistance - Excellent

- Heat of explosion - 3648 Kj/kg

Packaging

All "Armex Power" products are supplied in flexible sleeve durable packaging.

Transport

UN classification 1.1 D, UN 0241. Explosive, Blasting. Type E.

Small diameter emulsion explosives are used in civil engineering, tunneling, and mining (non-permitted). Suitable for use in all rock conditions, the Armex Power Plus series of products are designed to offer the user maximum effective performance, whilst retaining the intrinsic safety benefits of previous slurry and emulsion explosives.

| Standard dimensions | Cartridge weight |

| 27 х 225 mm | 155 gr |

| 30 х 225 mm | 191 gr |

| 32 х 200 mm | 193 gr |

| 32 х 400 mm | 386 gr |

| 34 х 225 mm | 245 gr |

| 34 х 400 mm | 436 gr |

| 36 х 225 mm | 275 gr |

| 38 х 225 mm | 306 gr |

| 40 х 400 mm | 595 gr |

| 50 х 225 mm | 540 gr |

| 50 х 450 mm | 1050 gr |

| 65 х 500 mm | 2000 gr |

| 75 х 200 mm | 1050 gr |

| 75 х 400 mm | 2000 gr |

| 90 х 290 mm | 2220 gr |

| 90 х 350 mm | 2500 gr |

Effective Performance

The production of new "Armex Power Plus" emulsion explosives is based upon unique technology. The use of this advanced technology means that the non-explosive ingredients are so intimately mixed as to produce exceptional shock and heave characteristics and subsequently, very effective rock breakage. In addition, after detonation, fume properties are excellent.

Thermodynamic and Technical Properties

It should be remembered that these values are calculated from thermodynamic data, and actual values will vary from them, according to the prevailing conditions in use.

- Ideal detonation velocity - 6437 m/s

- Ideal detonation pressure - 121400 atm

- Ideal detonation temperature - 2943 K

- Density - 1,20 gr/cm3

- Water resistance - Excellent

- Heat of explosion - 4433 Kj/kg

Transport

UN classification 1.1 D, UN 0241. Explosive, Blasting. Type E.